Air suspension components – Why replacement in pairs is important

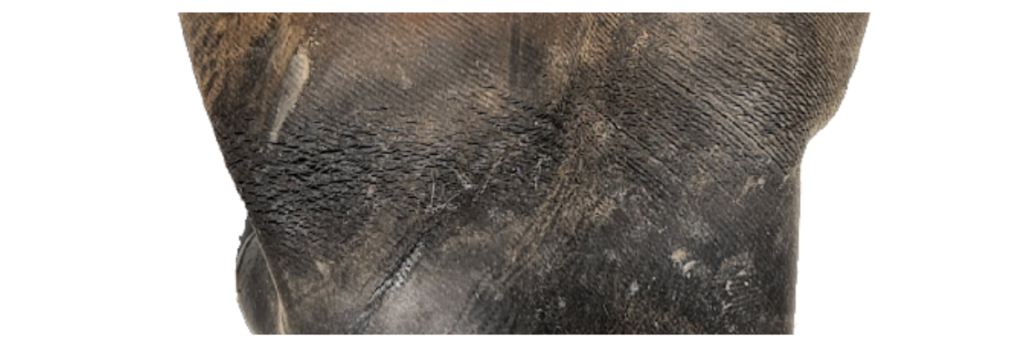

The main components of an air suspension system, the air springs and air struts, contain rubber sleeves. Rubber is a natural product prone to wear and tear causing the air sleeve to be the first component to wear out. Often, the rubber will dry rot and small cracks form where the air sleeve continuously rolls up and down the rolling piston during the spring movement. When the vehicle is being inspected, it is recommended that the air sleeves are checked for these small cracks and replaced to avoid the cracks developing into a bigger leak over time.

Typically, high-quality air springs should be replaced every six to ten years. Outside conditions including climate, road conditions, and constant abrasion of dirt and road debris also influence the functioning and life span of these air suspension components. Colder temperatures make the rubber stiffer and less flexible while hotter conditions will make the rubber dry out faster. Both hot and cold temperatures can give an already worn air sleeve the final push to burst.

Quality is of key importance when it comes to determining the product’s lifespan. In addition to rubber, other components including crimping rings, O-rings and piston material are also important. Although some cheap aftermarket air springs might look identical to the original part at first glance, the differences can be quite substantial! Making concessions such as using inferior rubber, lower grade parts and/or consolidation in piston design can result in lower burst pressure, difficult fitment, impaired damping comfort and more NVH (noise, vibration, and harshness). Arnott wants to ensure a safe drive with long-lasting products and therefore choses to use the highest quality rubber (Continental ContiTech) and other Tier 1 components for their air springs and struts.

When the air spring/strut is finally worn out, replacing in pairs is highly recommended. Even if the leak only occurs in one corner of the vehicle, replace the other side since the rubber of the air spring/strut on the opposite side has most likely been exposed to the same road and weather conditions as the failing side and has therefore faced the same wear and tear.

Replacing in pairs is commonly advised for conventional shock absorbers to avoid difference in dampening efficiency on the same axle. This dampening functionality difference between new and old is also the case for air suspension struts. If not replaced in pairs, the ride, handling, and stability of the vehicle is substantially impaired which could lead to unpredictable driving behaviour and dangerous situations.

Although replacing in pairs is not mandatory for most Arnott parts, it is still highly recommended. It will not only ensure a safe, comfortable ride but likely also prevent another trip to the workshop.

This information is provided to you by Arnott – Suspension Products. With more than 30 years of experience in engineering, designing, and manufacturing high quality suspension components for the aftermarket, Arnott is the technical expert when it comes to suspension systems.