By Steve Samudio, Paul Spence and Denise D. Wight

Water restrictions or not, there’s good reason to make a commitment to water conservation and water reclamation in the carwash industry. Water and sewer costs have increased an average of 50 per cent since 2008. Water and sewer costs are becoming the number one operating expense for carwash operators. Companies should be actively managing water use because doing nothing now will cost more later. There are many steps operators can take; from checking for leaks and limiting flow through nozzles to RO reject recovery, but the most effective way is through water reclamation.

What is reclaim? The definition of reclaim is “to retrieve or recover something lost.” Reclaim, by carwash industry definition, is the re-use of previously used water in the carwash process. It is important to note that a small percentage of the wash water is lost due to evaporation and carryout. Let’s talk about the water we can re-capture and re-use. There are three main sources; Reverse osmosis (RO) reject water, rainwater and reclaimed carwash water.

- Reverse osmosis (RO) reject water: A Reverse osmosis system uses city water in the process of making spot-free water. The byproduct of this process is called reject water. RO reject water has been treated for chlorine by the carbon filter and has gone through a five-micron prefilter but is high in total dissolved solids (TDS). The high TDS negatively impacts chemical performance and therefore should not be used for chemical applications. The best use for RO reject water is a rinse after the wash process and before the waxes, clear-coats and spot-free rinse. RO reject does a great job of prepping the vehicle for the final spot free rinse.

- Rainwater harvesting: Rainwater can be used as an alternative water source for your carwash. Rainwater is soft water, so it can be used for many different applications. Capturing and storing the rainwater to reuse in your carwash is a form of water reclamation. Some counties have restrictions on use of rainwater, check with them first before implementing rainwater harvesting.

- Reclaimed wash water: All water that was used in the carwash; the reclaimed wash water, the city water mixed with chemicals, spot free water (RO), and RO reject water. All can be repurposed not just for the carwash, but in many cities, can also be used for irrigation systems at your facility. Check with your local municipality for any restrictions. The ability to utilize reclaim water for landscaping keeps your reclaim tanks fresher and decreases your discharge to sewer (getting you ever closer to true zero discharge). This helps the environment and helps your pocketbook!

There are two steps to cleaning the used wash water; both steps are equally important:

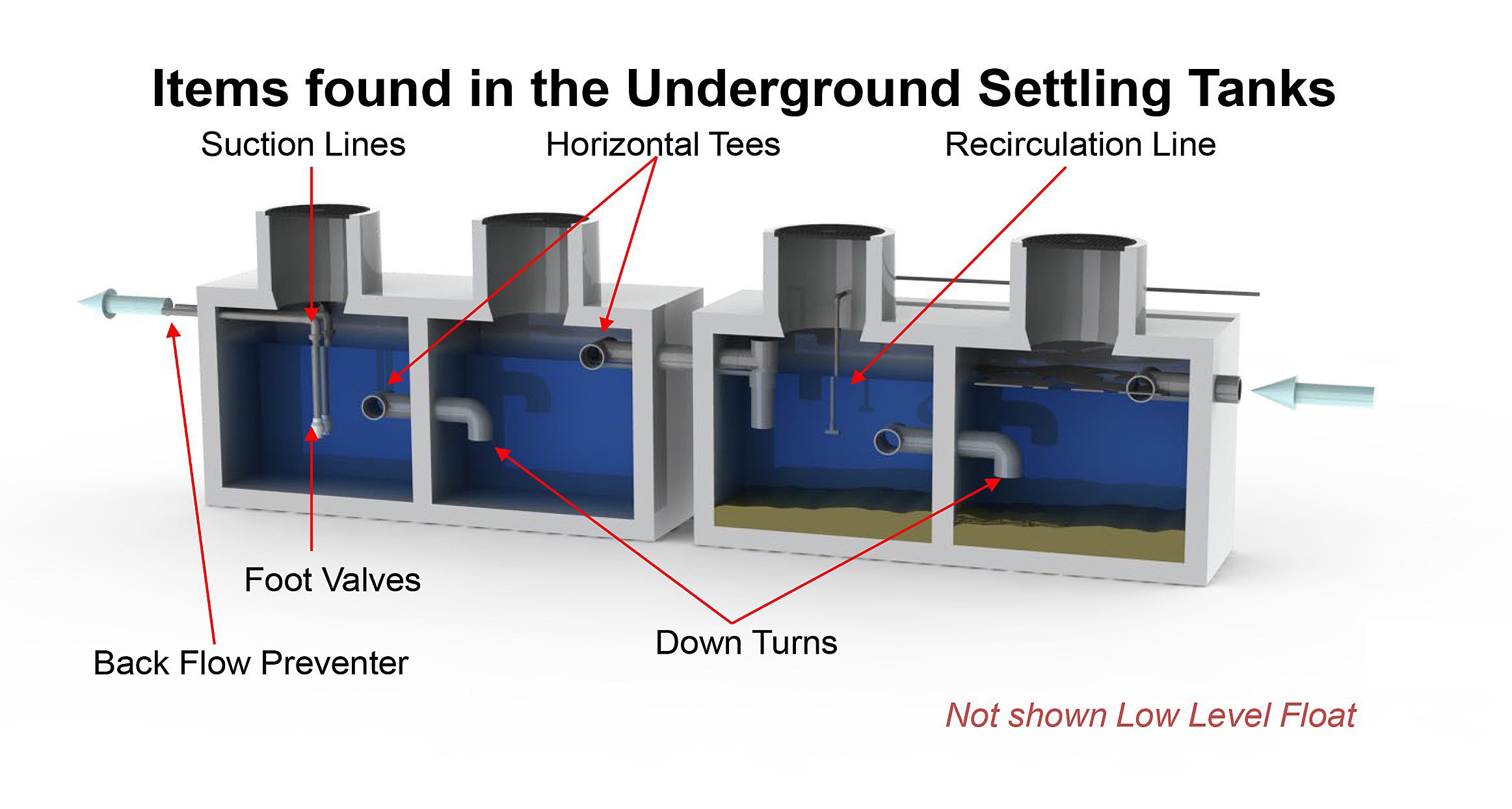

- First step are the settling tanks. These are typically underground. Above ground tanks can also be used when digging is not an option. The goal of the settling tanks is to separate the oil and floatable material from the water and to give the suspended solids in the water time to settle to the bottom of the tanks. (Note: If the first step is done incorrectly, the end-result will be diminished water quality.)

- The second step for cleaning the wash water is the reclaim system itself. The reclaim system will bring the water down to a certain size particulate (micron) that is appropriate for your wash. There are several different ways to do that: cyclonic separation, multimedia and filter bags. Keep in mind that the smaller the micron size, the higher the quality the reclaim water will be.

Reclaiming water is a necessary part of the modern-day carwash. By minimizing the amount of water discharged out to the sewer you are reducing waste, taking care of the environment and saving money. Understanding how reclaim works and spending the time to find the right people to help you create a properly designed carwash is extremely important. If you get this wrong, it’s expensive and time consuming to correct.

How to Reclaim Water

There are many ways to reclaim carwash water these days and while there are multiple technologies available, few produce the quality water that most operators want and need to be successful. There are pros and cons to all technology but after much practical field experience, we’ve found the process described below, if followed correctly, is by far the most effective.

The first step in this reclamation process is to settle out solids. By using gravity and time as our friend, settling tanks are the answer. The combination of both gravity and time allows for heavier solids to settle to the bottom of the tanks enabling you to get rid of most of the contaminants. Using Stokes Law, the tanks are sized depending on water flow/volume. Ideally, when the water enters the first set of tanks, it will take 60 minutes to travel to the last tank. This allows enough time to settle solids but also prevent stagnant water which will begin to develop bacterial growth and will lead to foul smelling water.

The second step to reclaiming the wash water is using cyclonic separation to refine the wash water. Not only is it very effective, it is virtually maintenance free. There are many cyclones on the market, make sure you utilize a system that cleans down to the five-micron level. Micron size has a direct correlation to wash quality and carwash equipment failure. The smaller the micron achieved consistently, the more effective the reclaim system will be. Five-micron quality water allows for more reclaim water to be used, is suitable for high pressure pumps and keeps your wash bay and equipment cleaner. The water is pulled from the underground tanks using a single pump setup, it is then sent through the cyclones to spin out remaining solids. By using a single pump setup, five-micron cyclones and a VFD, you can consistently recirculate the water in the tanks while also feeding the carwash simultaneously. We call this an on-demand system. There are systems that we call batch systems due to them having to process and clean water, store the water, and then deliver to the wash. This can lead to problems such as not enough water to feed the wash, and or stagnant water that starts to develop bacteria, which I mentioned…… yes, creates foul smelling water.

In addition to removing the solids to five microns, you must also recirculate and aerate the reclaim water in the settling tanks. The most effective recirculation process runs 24/7 and has ozone introduced to treat and kill bacteria. Yes, the most effective systems run 24/7. I like to explain to customers that it’s like a swimming pool: “You know that pump you have that comes on and off throughout the day? That is to prevent water from becoming stagnant.” The same thing with an effective reclaim system except now you’re dealing with highly contaminated water and you want to circulate and clean this water as often as possible. While recirculation is going on ozone is introduced into the recirculation stream. Ozone is a gas that is produced on the reclaim system by first concentrating ambient air into dry, clean, pure O2. The gas is pumped into the ozone system where the O2 molecules are split by high voltage arcing (corona discharge) and formed back into O3 molecules, which is ozone. Ozone is a contact killing agent that is 20 times stronger than chlorine. It is 3000 times faster to purify water than chlorine. Bottom line is that ozone is the strongest, fastest, commercially available disinfectant and oxidant for water treatment.

Lastly, as with any good strategy, how it is implemented is crucial. Train employees to be water champions and help look for leaks in the wash bay, in the bathrooms and on the property. Educate your employees as well as your customers. Install signage and monitor and meter your results. Remember, work with a partner that will evaluate your site from entrance to exit to ensure the proper water treatment solutions are put in place. Reclaiming water in the carwash industry isn’t difficult, you just need the right strategy!

Steve Samudio is the director of operations for New Wave Industries. Steve has helped engineer NWI products for 20 years and is named on some of NWI patents. Steve’s vast experience with water treatment in the carwash industry positions him to be a leading expert for years to come. He can be contacted at ssamudio@purclean.com .

Paul Spence is a technical sales manager for New Wave Industries. Paul has been in the carwash industry for over 23 years. He’s done everything from install tunnels and automatic carwashes from the ground up, to providing technical training and troubleshooting classes throughout North America. He can be contacted at pspence@purclean.com .

Denise D. Wight is the vice president of New Wave Industries, manufacturer of the PurClean Spot Free Rinse system and the PurWater reclaim system. She has been in the carwash industry for over 30 years and has extensive experience with water related issues as well as point of sales systems for the carwash industry. She can be contacted at Dwight@purclean.com .